4

0

0

The Processes Active In The Plastic To Oil Conversion Plant

39

China

0

The latest of the plastic to oil conversion plant machines have the ability to satisfy various demands in association to several customers. These plants can be found in varying capacities and different types of operating methods. Three of the main types include:

1. Batch Plastic To Oil Conversion Pyrolysis Plant

These plants are great when labor costs are low, and when the waste plastic amounts are small. These plants possess a specified standard when it comes to raw materials which involves a minimal water content.

2. Semi-Continuous Pyrolysis Plant

Working efficiencies of this equipment is faster in comparison to the batch-operating plants but are less costly in comparison to the continuous-pyrolysis plants.

3. Continuous Pyrolysis Plant

For customers who definitely have huge amounts of waste plastic to discard, plus it costs an excessive amount of to get workers so that you can operate the plant, then these plants are perfect because of their increased automation abilities, low labor cots and efficient working speeds.

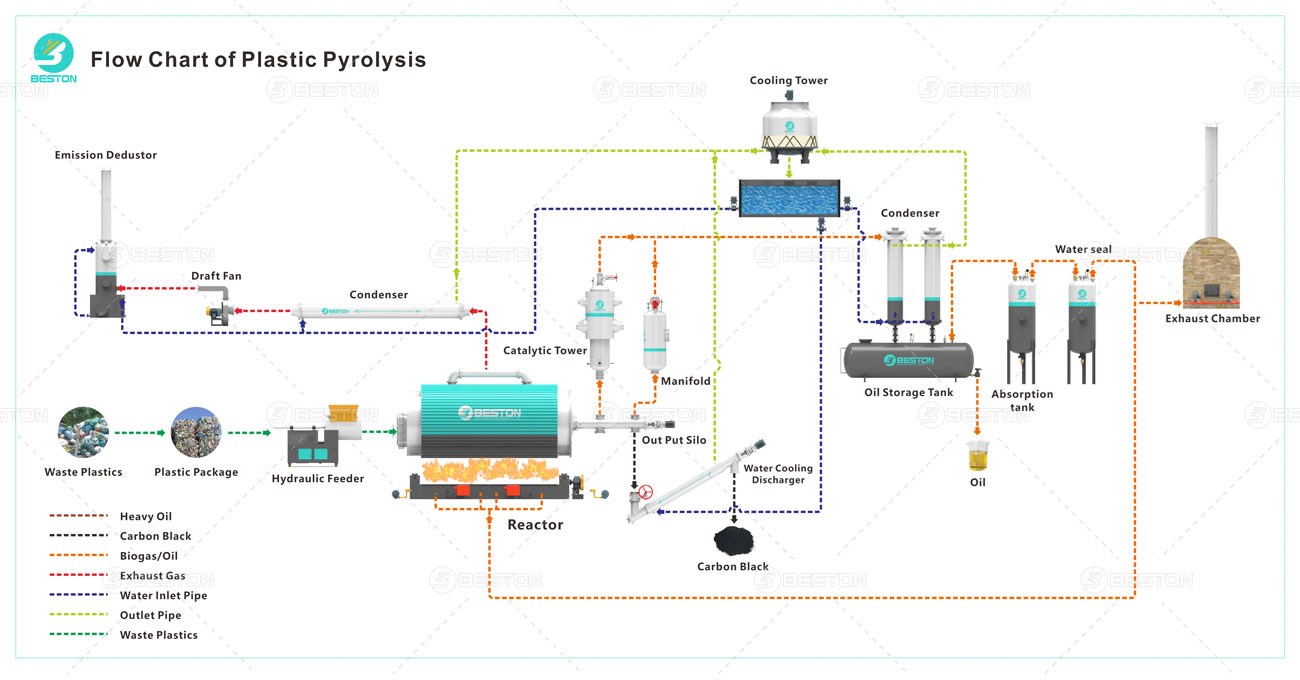

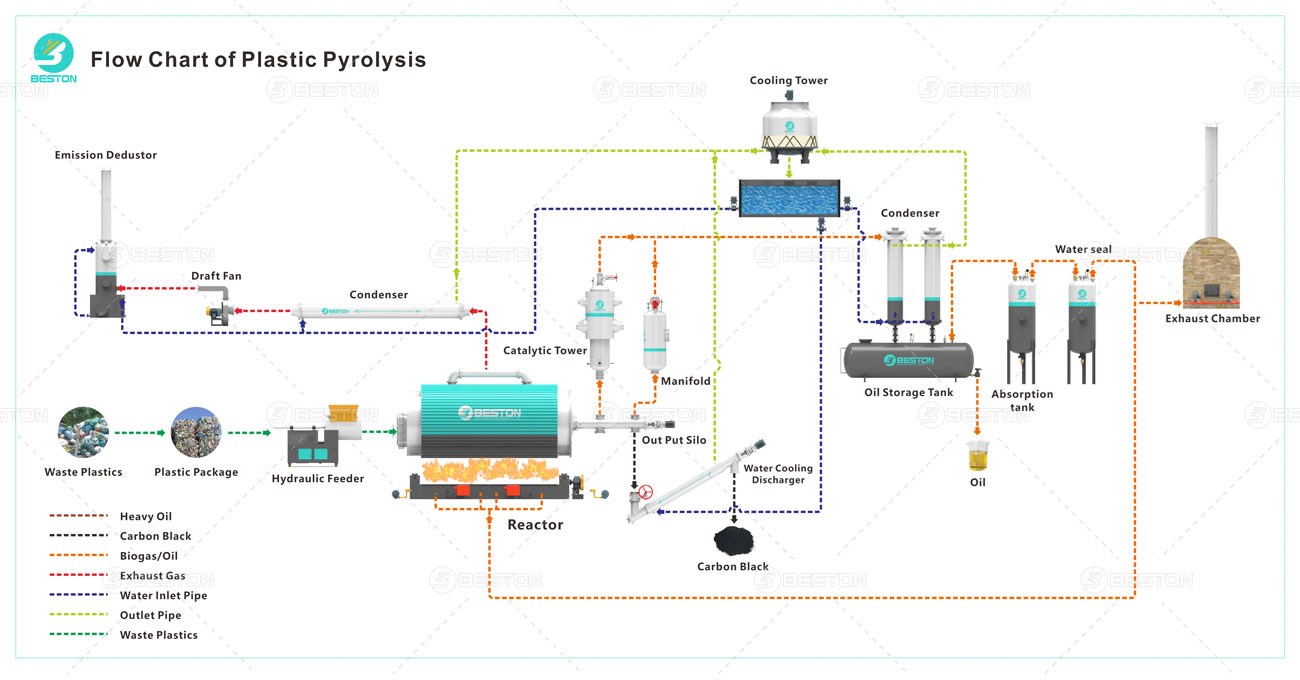

The Working Procedure Of The Plastic To Oil Conversion Plant

Before plastic waste could be fed in a pyrolysis reactor, the water content should be low enough. It might be necessary to get the right dryer to dry the types of materials.

The pyrolysis reactor on the plastic to oil machine are heated using LPG fuels, wood fuels or other sorts of fuel materials. Once the reactor reaches 200 degrees, the lowest volume of gas-oil is produced. A temperature of between 280 and 300 degrees is considered the best oil-yield rate-interval. It is from here the manifold has the capacity to separate the lighting-oil gas from the heavy-oil gas. It really is from this point these heavy-oil gases will liquify then drop-down into a large-oil tank. The light-oil gas will rise right into a condenser, where it is going to liquify and collect inside of the oil-tank.

Any combustible gas is processed by way of a hydro-seal. After the dedusting and de-sulphuration process, it is then recycled to deliver heat on the reactor. Once these processes are completed, you will be left by using a plastic-pyrolysis oil that could then be applied as fuel. For all those customers thinking about further improving the standard of this oil, it can be suggested to use a Waste Plastic To Diesel Machine which will further refine the plastic oils.

Despite the fact that there are some variations among these plants, below are a few from the shared benefits, which includes added to why these machines have grown to be so well liked around the markets.

• High Oil Yield Rate

Oil yield rates will vary in line with the material type. The oil yield rates for PE, PP and PS is between 50% and 75%. As the oil yield rated for ABS is 40%.

• Security Design

The whole procedure of converting plastics into oil is completed under high-temperature conditions. For that reason, the casing is made in a way it will protect any operators during operation. The hydro-seal also removes the sulfur out of the gas so the combustible gases usually do not cause damages for the reactor.

• Sealing System

These plants operate in an oxygen-free environment. If any oxygen is permitted to go into the reactor it can result in damaging effects. Because of this, the sealing systems on these plants are vital.

1. Batch Plastic To Oil Conversion Pyrolysis Plant

These plants are great when labor costs are low, and when the waste plastic amounts are small. These plants possess a specified standard when it comes to raw materials which involves a minimal water content.

2. Semi-Continuous Pyrolysis Plant

Working efficiencies of this equipment is faster in comparison to the batch-operating plants but are less costly in comparison to the continuous-pyrolysis plants.

3. Continuous Pyrolysis Plant

For customers who definitely have huge amounts of waste plastic to discard, plus it costs an excessive amount of to get workers so that you can operate the plant, then these plants are perfect because of their increased automation abilities, low labor cots and efficient working speeds.

The Working Procedure Of The Plastic To Oil Conversion Plant

Before plastic waste could be fed in a pyrolysis reactor, the water content should be low enough. It might be necessary to get the right dryer to dry the types of materials.

The pyrolysis reactor on the plastic to oil machine are heated using LPG fuels, wood fuels or other sorts of fuel materials. Once the reactor reaches 200 degrees, the lowest volume of gas-oil is produced. A temperature of between 280 and 300 degrees is considered the best oil-yield rate-interval. It is from here the manifold has the capacity to separate the lighting-oil gas from the heavy-oil gas. It really is from this point these heavy-oil gases will liquify then drop-down into a large-oil tank. The light-oil gas will rise right into a condenser, where it is going to liquify and collect inside of the oil-tank.

Any combustible gas is processed by way of a hydro-seal. After the dedusting and de-sulphuration process, it is then recycled to deliver heat on the reactor. Once these processes are completed, you will be left by using a plastic-pyrolysis oil that could then be applied as fuel. For all those customers thinking about further improving the standard of this oil, it can be suggested to use a Waste Plastic To Diesel Machine which will further refine the plastic oils.

Despite the fact that there are some variations among these plants, below are a few from the shared benefits, which includes added to why these machines have grown to be so well liked around the markets.

• High Oil Yield Rate

Oil yield rates will vary in line with the material type. The oil yield rates for PE, PP and PS is between 50% and 75%. As the oil yield rated for ABS is 40%.

• Security Design

The whole procedure of converting plastics into oil is completed under high-temperature conditions. For that reason, the casing is made in a way it will protect any operators during operation. The hydro-seal also removes the sulfur out of the gas so the combustible gases usually do not cause damages for the reactor.

• Sealing System

These plants operate in an oxygen-free environment. If any oxygen is permitted to go into the reactor it can result in damaging effects. Because of this, the sealing systems on these plants are vital.

Signatur