7

0

0

A Biochar Making Machine: An Effective Solution to Reduce Greenhouse Gas Emissions from Decomposing Biomass

100

Beston Machinery

0

The decomposition of biomass in the presence of oxygen leads to the release of substantial amounts of carbon dioxide (CO2) and methane (CH4), contributing to climate change. However, when biomass decomposes in the absence of oxygen, it produces a carbon-rich residue known as biochar. Biochar can be a valuable tool in mitigating greenhouse gas emissions and improving soil health. This article explores the benefits of using a great biochar machines for sale to produce biochar continuously and sustainably.

Understanding Biochar and its Environmental Benefits:

Biochar is essentially a form of charcoal derived from the thermal decomposition of biomass in the absence of oxygen. Unlike the natural decomposition process, which releases greenhouse gases, biochar has the potential to reduce their formation when applied to soil. It possesses a porous structure that enhances water and nutrient retention in the soil, promoting healthier soil conditions and supporting plant growth. As a result, biochar application can reduce the need for additional water and fertilizer, making agricultural practices more sustainable.

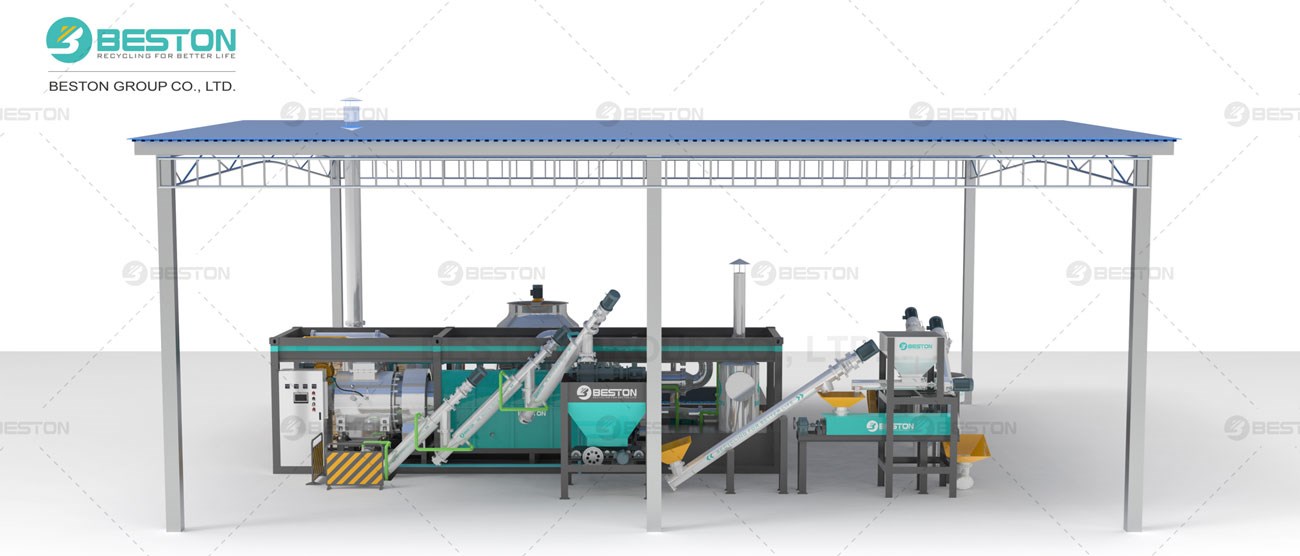

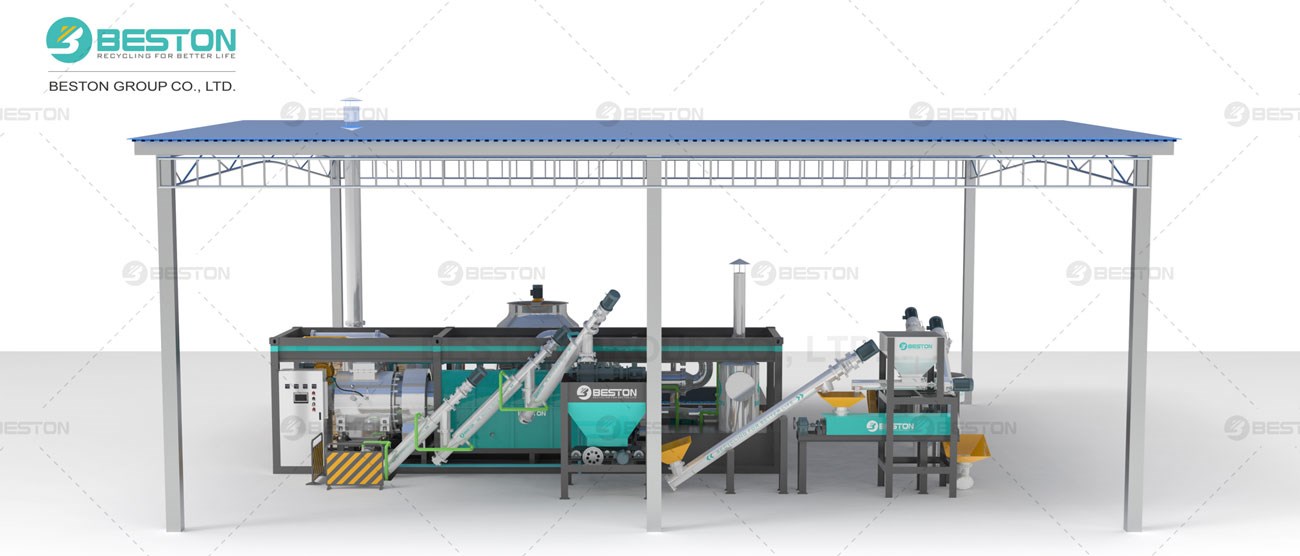

Biochar Making Machines and Pyrolysis Systems:

Biochar making machines, also known as pyrolysis systems, utilize a process called pyrolysis to convert biomass into biochar. These machines bake the biomass at high temperatures without oxygen, leading to the production of gases, liquids, and other solid by-products. Pyrolysis ensures that oxygen is excluded, enhancing biochar production.

The ovens used in biochar production are low-tech and can handle various types of biomass, including yard waste, agricultural residues, plastic, old tires, and organic sludge from industries and municipalities. By diverting these materials from landfills, biochar making machines contribute to reducing environmental concerns associated with waste disposal.

Operational Process and Utilization of By-products:

To generate the necessary heat, biochar making machines employ a combination of gas, wood, and diesel. The by-products of the pyrolysis process can also be recycled to supplement heat generation, making the production process self-sustaining. However, it is crucial to ensure that the biomass materials used in these machines have a moisture content below 20%. Dryers may be employed to reduce moisture levels, facilitating easier combustion of the biomass.

When temperatures within the machine exceed 100 degrees Celsius, charcoal and combustible gases are produced. The gases need to undergo purification to remove sulfur content and pass through a condensing system to eliminate tar. The remaining gas can be utilized in furnaces or for drying biomass, reducing fuel costs. The biochar itself is cooled using integrated cooling systems until it reaches a temperature below 30 degrees Celsius.

In addition to biochar, biochar making machines produce by-products such as tar and wood vinegar, which have their own applications. Biochar has higher calorific value compared to coal, making it more environmentally friendly. Its use as a fertilizer is attributed to the presence of various micro-elements like phosphorus, nitrogen, manganese, calcium, and others, which contribute to improving soil quality.

Continuous Operation and Product Retrieval:

Most biochar making machines operate continuously, allowing for uninterrupted production without the need to halt the process to retrieve the products produced during pyrolysis. This continuous operation ensures efficiency and increases the overall output of biochar, making it a practical solution for large-scale production.

Conclusion:

A biochar making machine offers a promising solution to address the issue of greenhouse gas emissions resulting from the decomposition of biomass. By utilizing pyrolysis technology, these machines can convert biomass into biochar continuously and sustainably. The resulting biochar can be applied to soil, promoting improved soil health, water retention, and nutrient availability while reducing the need for additional water and fertilizer. Additionally, the production process of biochar helps minimize waste by diverting biomass from landfills. With its potential to mitigate climate change and enhance agricultural sustainability, biochar making machines play a crucial role in reducing greenhouse gas emissions while simultaneously improving soil quality.

Understanding Biochar and its Environmental Benefits:

Biochar is essentially a form of charcoal derived from the thermal decomposition of biomass in the absence of oxygen. Unlike the natural decomposition process, which releases greenhouse gases, biochar has the potential to reduce their formation when applied to soil. It possesses a porous structure that enhances water and nutrient retention in the soil, promoting healthier soil conditions and supporting plant growth. As a result, biochar application can reduce the need for additional water and fertilizer, making agricultural practices more sustainable.

Biochar Making Machines and Pyrolysis Systems:

Biochar making machines, also known as pyrolysis systems, utilize a process called pyrolysis to convert biomass into biochar. These machines bake the biomass at high temperatures without oxygen, leading to the production of gases, liquids, and other solid by-products. Pyrolysis ensures that oxygen is excluded, enhancing biochar production.

The ovens used in biochar production are low-tech and can handle various types of biomass, including yard waste, agricultural residues, plastic, old tires, and organic sludge from industries and municipalities. By diverting these materials from landfills, biochar making machines contribute to reducing environmental concerns associated with waste disposal.

Operational Process and Utilization of By-products:

To generate the necessary heat, biochar making machines employ a combination of gas, wood, and diesel. The by-products of the pyrolysis process can also be recycled to supplement heat generation, making the production process self-sustaining. However, it is crucial to ensure that the biomass materials used in these machines have a moisture content below 20%. Dryers may be employed to reduce moisture levels, facilitating easier combustion of the biomass.

When temperatures within the machine exceed 100 degrees Celsius, charcoal and combustible gases are produced. The gases need to undergo purification to remove sulfur content and pass through a condensing system to eliminate tar. The remaining gas can be utilized in furnaces or for drying biomass, reducing fuel costs. The biochar itself is cooled using integrated cooling systems until it reaches a temperature below 30 degrees Celsius.

In addition to biochar, biochar making machines produce by-products such as tar and wood vinegar, which have their own applications. Biochar has higher calorific value compared to coal, making it more environmentally friendly. Its use as a fertilizer is attributed to the presence of various micro-elements like phosphorus, nitrogen, manganese, calcium, and others, which contribute to improving soil quality.

Continuous Operation and Product Retrieval:

Most biochar making machines operate continuously, allowing for uninterrupted production without the need to halt the process to retrieve the products produced during pyrolysis. This continuous operation ensures efficiency and increases the overall output of biochar, making it a practical solution for large-scale production.

Conclusion:

A biochar making machine offers a promising solution to address the issue of greenhouse gas emissions resulting from the decomposition of biomass. By utilizing pyrolysis technology, these machines can convert biomass into biochar continuously and sustainably. The resulting biochar can be applied to soil, promoting improved soil health, water retention, and nutrient availability while reducing the need for additional water and fertilizer. Additionally, the production process of biochar helps minimize waste by diverting biomass from landfills. With its potential to mitigate climate change and enhance agricultural sustainability, biochar making machines play a crucial role in reducing greenhouse gas emissions while simultaneously improving soil quality.

Signatur