10

0

0

Exploring Crucial Factors in Selecting a Pyrolysis Plant for Purchase

100

Beston Machinery

0

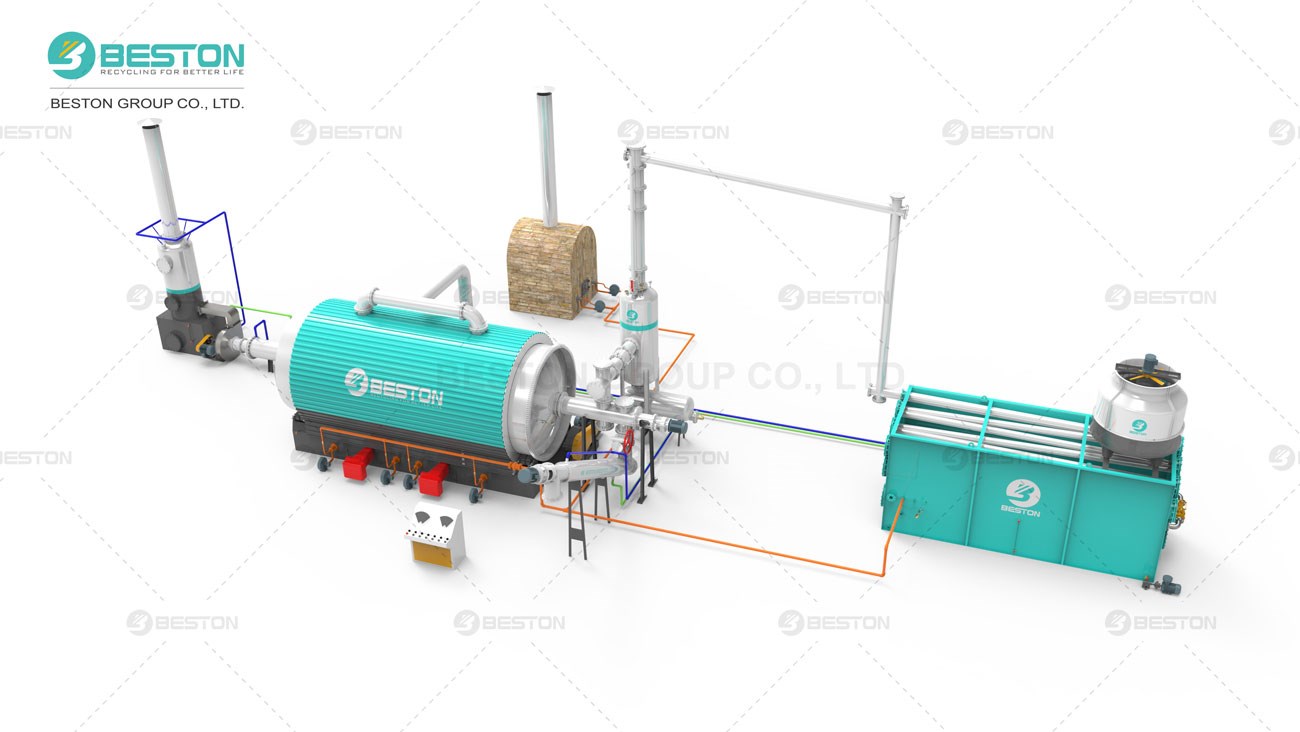

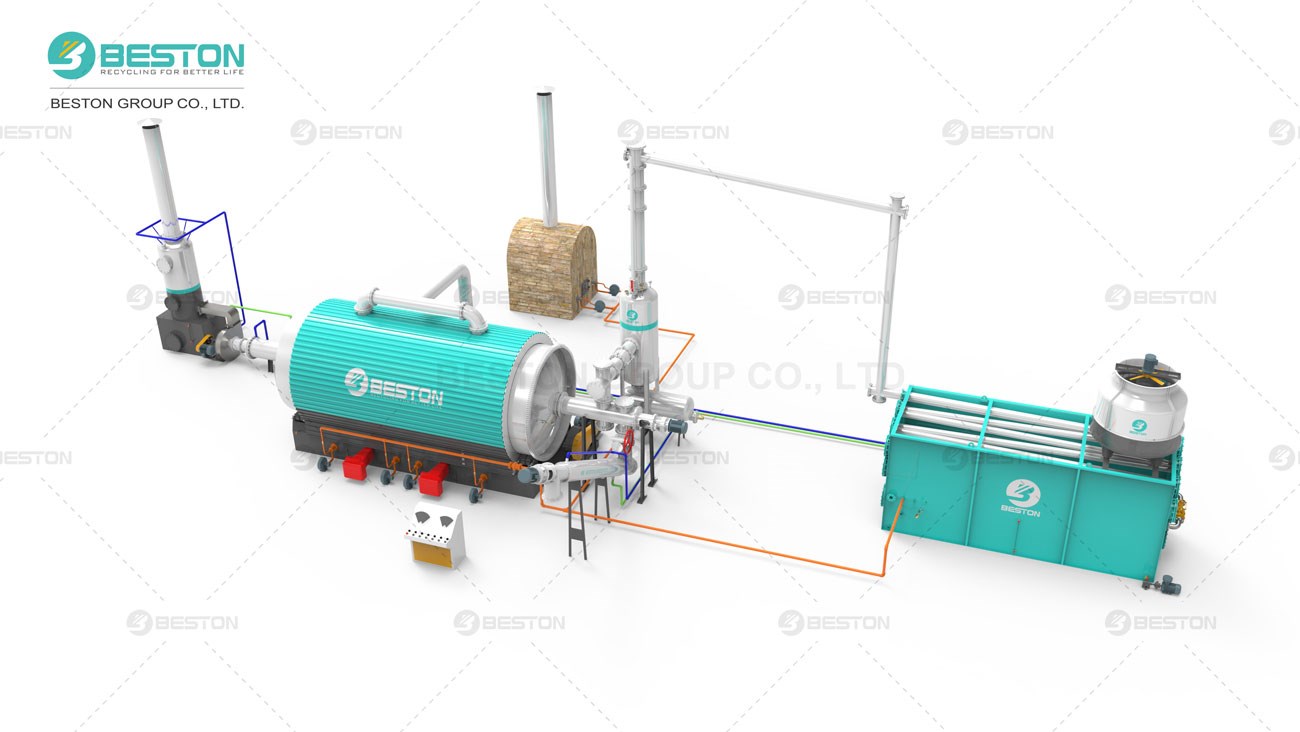

In today's quest for sustainable energy solutions, pyrolysis stands out as a promising process to convert biomass waste into valuable resources like bio oil, bio gas, and biochar. Pyrolysis operates within a low-oxygen environment, disintegrating organic materials into their elemental components. This process has garnered attention not only for its potential in waste management but also for its role in energy recovery and reducing greenhouse gas emissions.

However, before diving into the world of Beston pyrolysis plant, it's essential to consider various aspects to make an informed decision about your investment. This article will delve into the significant factors that warrant thorough assessment before acquiring a pyrolysis plant.

The Green Promise of Pyrolysis

Pyrolysis holds significant promise due to its ability to transform various types of organic waste into valuable resources. This process can effectively convert biomass waste into bio oil, bio gas, and biochar. Moreover, it finds application in processing municipal solid waste, sewage sludge, and other organic waste materials characterized by high moisture content.

Benefits of pyrolysis include the production of fuels, energy recovery from wastewater, reduction of greenhouse gas emissions, and a decreased reliance on fossil fuels for energy generation. Pyrolysis aligns well with the global push towards sustainable and environmentally friendly waste management practices.

Cost Considerations and Capital Investment

While pyrolysis offers substantial environmental benefits, it's crucial to acknowledge that pyrolysis plants generally come with a higher capital cost compared to incineration plants. This disparity in cost is attributed to the complex nature of pyrolysis equipment, which includes components like heat exchangers, pumps, and intricate system elements.

Nonetheless, the long-term benefits of pyrolysis, including reduced carbon emissions and increased energy recovery, often justify the higher initial investment. It's essential to weigh these cost factors against the environmental advantages to determine the feasibility of a pyrolysis plant for your specific context.

Environmental Impact and Emission Reduction

The environmental implications of pyrolysis are substantial. When compared to open burning of biomass waste materials, pyrolysis production emits around 24% less carbon dioxide into the atmosphere. This reduction in greenhouse gas emissions makes pyrolysis a compelling choice for sustainable waste management and energy production. Take a view at the quality waste pyrolysis plant UK.

Customization and Operational Process

When considering a pyrolysis plant purchase, customization plays a pivotal role. The plant's configuration should align with your specific operational needs. This entails analyzing factors like feedstock preparation, operation modes, maintenance requirements, and safety protocols.

The customization process involves defining the type of biomass to be processed, the desired energy output, and the available space for plant installation. Pyrolysis plants can be designed to process various biomass materials, including wood chips, grasses, palm kernels, and even municipal solid waste. Understanding the material requirements and end products will guide the customization process for optimal efficiency.

Fuel Selection and Efficiency

The choice of fuel for pyrolysis plants is critical. Fuels like propane and natural gas are popular options due to their minimal particulate emissions, clean combustion, and safety features. These fuels also offer energy efficiency and competitive pricing compared to other energy sources.

Final Verdict: An Informed Decision

In the realm of sustainable energy solutions, pyrolysis plants hold substantial potential. However, selecting the right plant involves a careful analysis of capital investment, customization options, environmental impact, and fuel efficiency. The decision-making process should align with your operational needs, long-term goals, and commitment to sustainable waste management practices. With the right considerations in place, a pyrolysis plant can become a cornerstone in your journey towards a greener future.

However, before diving into the world of Beston pyrolysis plant, it's essential to consider various aspects to make an informed decision about your investment. This article will delve into the significant factors that warrant thorough assessment before acquiring a pyrolysis plant.

The Green Promise of Pyrolysis

Pyrolysis holds significant promise due to its ability to transform various types of organic waste into valuable resources. This process can effectively convert biomass waste into bio oil, bio gas, and biochar. Moreover, it finds application in processing municipal solid waste, sewage sludge, and other organic waste materials characterized by high moisture content.

Benefits of pyrolysis include the production of fuels, energy recovery from wastewater, reduction of greenhouse gas emissions, and a decreased reliance on fossil fuels for energy generation. Pyrolysis aligns well with the global push towards sustainable and environmentally friendly waste management practices.

Cost Considerations and Capital Investment

While pyrolysis offers substantial environmental benefits, it's crucial to acknowledge that pyrolysis plants generally come with a higher capital cost compared to incineration plants. This disparity in cost is attributed to the complex nature of pyrolysis equipment, which includes components like heat exchangers, pumps, and intricate system elements.

Nonetheless, the long-term benefits of pyrolysis, including reduced carbon emissions and increased energy recovery, often justify the higher initial investment. It's essential to weigh these cost factors against the environmental advantages to determine the feasibility of a pyrolysis plant for your specific context.

Environmental Impact and Emission Reduction

The environmental implications of pyrolysis are substantial. When compared to open burning of biomass waste materials, pyrolysis production emits around 24% less carbon dioxide into the atmosphere. This reduction in greenhouse gas emissions makes pyrolysis a compelling choice for sustainable waste management and energy production. Take a view at the quality waste pyrolysis plant UK.

Customization and Operational Process

When considering a pyrolysis plant purchase, customization plays a pivotal role. The plant's configuration should align with your specific operational needs. This entails analyzing factors like feedstock preparation, operation modes, maintenance requirements, and safety protocols.

The customization process involves defining the type of biomass to be processed, the desired energy output, and the available space for plant installation. Pyrolysis plants can be designed to process various biomass materials, including wood chips, grasses, palm kernels, and even municipal solid waste. Understanding the material requirements and end products will guide the customization process for optimal efficiency.

Fuel Selection and Efficiency

The choice of fuel for pyrolysis plants is critical. Fuels like propane and natural gas are popular options due to their minimal particulate emissions, clean combustion, and safety features. These fuels also offer energy efficiency and competitive pricing compared to other energy sources.

Final Verdict: An Informed Decision

In the realm of sustainable energy solutions, pyrolysis plants hold substantial potential. However, selecting the right plant involves a careful analysis of capital investment, customization options, environmental impact, and fuel efficiency. The decision-making process should align with your operational needs, long-term goals, and commitment to sustainable waste management practices. With the right considerations in place, a pyrolysis plant can become a cornerstone in your journey towards a greener future.

Signatur